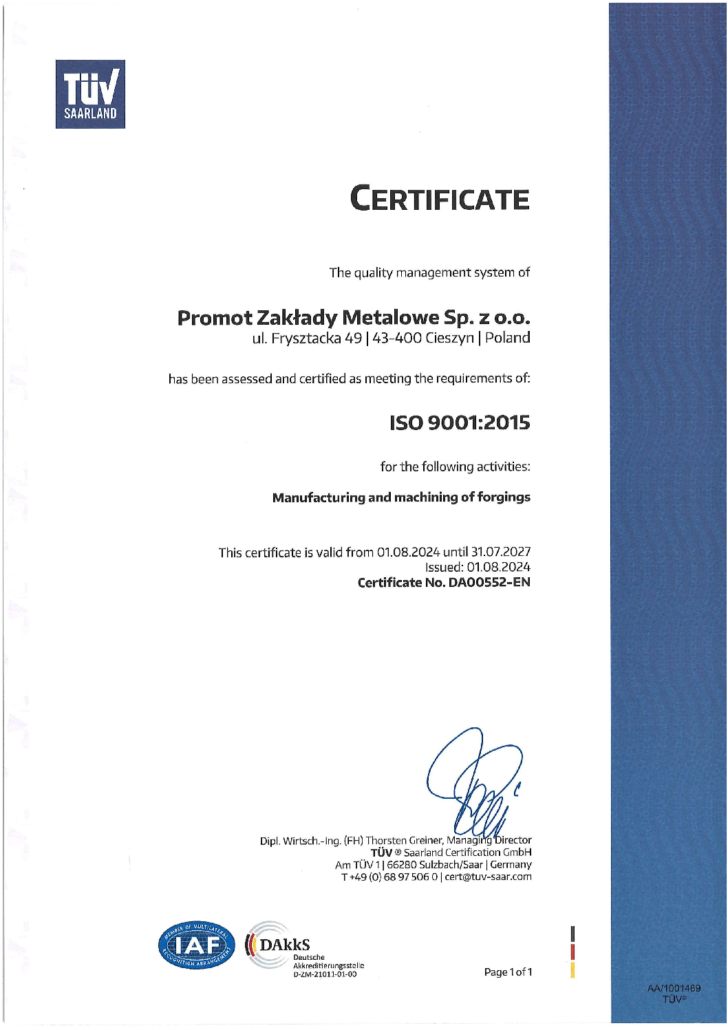

The company is managed in accordance with the requirements of the quality management system according to ISO 9001:2015 and IATF 16949:2016. In addition, Promot-Zakłady Metalowe has implemented and is certified in accordance with the requirements of BIQS (General Motors) and Pressure Equipment Directive PED 2014/68/EU, Annex I, pt. 4.3 and AD 2000-Merkblatt W0.

The effectiveness of our quality management system has been confirmed by the client General Motors by awarding prizes in 2019,2020,2021,2022 and 2023:

- GM Supplier Quality Excellence Award for 2018

- GM Supplier Quality Excellence Award for 2019

- GM Supplier Quality Excellence Award for 2020

- GM Supplier Quality Excellence Award for 2021

- GM Supplier Quality Excellence Award for 2022

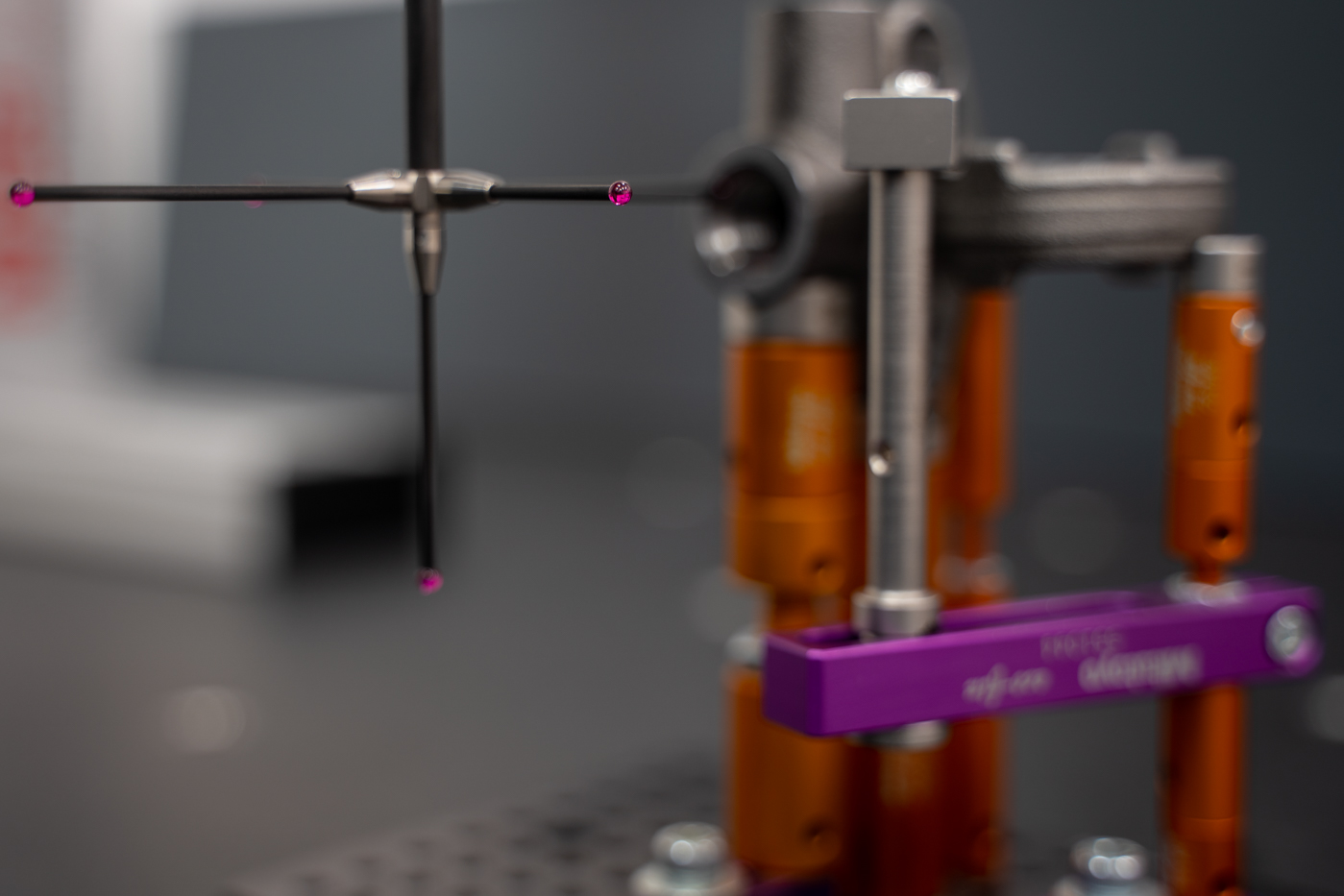

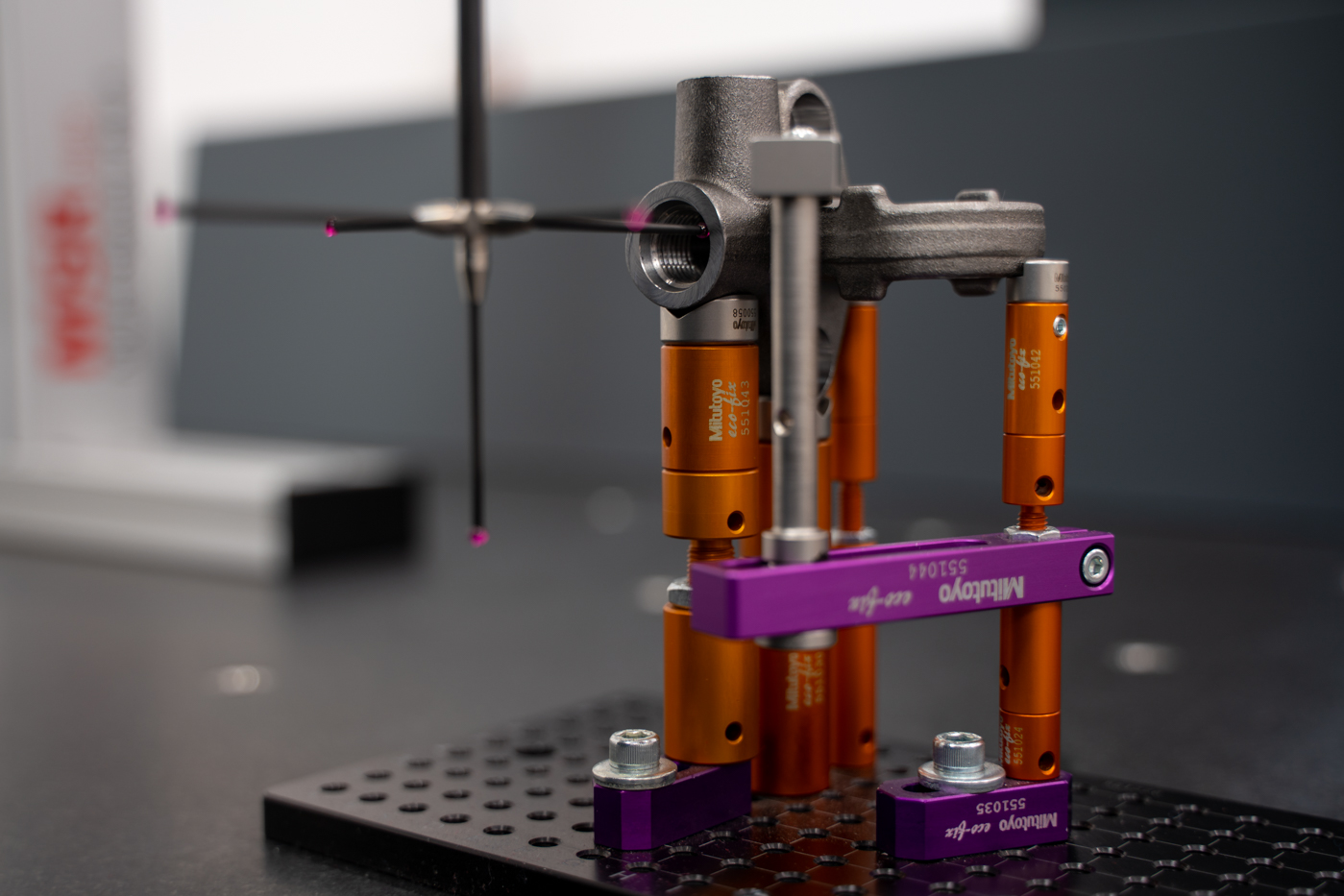

The internal laboratories are equipped with control and measuring instruments that guarantee the possibility of continuous measurements of our processes.

The basic control and measuring instruments are

- 3D coordinate measuring machine Zeiss Contura RDS CMM

- Zeiss Vista CMM 3D coordinate measuring machine

- Zeiss Duramax CMM 3D coordinate measuring machine

- Aberlink 3D-coordinate measuring machine

- 3D Scanner

- Spectrotest TXC35 spectrometer

- Hardness measuring instrument

- PVC Profiles Mahr

- Mitutoyo roughness measuring device

- MahrSurf roughness tester

The products are measured at the workplaces and in the laboratory according to the control plan.